The TR160S is a streamlined version and the next evolution of the hugely popular TR160 series of racing cockpits from Trak Racer. Adding items like the flight simulator control mounts transforms this cockpit from a weekend sim racer to a serious flight simulation cockpit.

Contents:

– Unboxing

– Frame Build Process

– Seat Assembly

– Pedal Mount

– Yoke/Wheel Mount

– Accessories

– Trak Mat

– Using the TR160s

– Comfort

– Conclusions

About The Author:Sean

Sean is a pilot with over two decades of experience in aviation and senior technology roles within Airlines and Non-Profit sectors. He’s a lifelong flight simmer and avid VR user, blending his passion for flying with cutting-edge technology. From cockpit to virtual skies, Sean loves all things Tech and Aviation.

If you would like to support our work at Boosted Media at no additional cost, follow the affiliate link below for your region and we will earn a small commission from your purchase.

Please make sure you accept cookies when prompted or we won’t receive the commission.

Packaging shipping:

Everything arrived within 7 days of the order being placed.

13 boxes in total of varying weights and sizes, only 1 looks like it had a hard time enroute to my place but given how well these are packaged no damage was encountered.

Initial layout and Preparation:

Upon finishing the creation of my recycling mountain for my dogs to scale and turn into a wasteland, I began the build by laying out each part to get a sense of the scale of the job that was before me.

As this is now my second flight simulator cockpit (coming previously from a Next level Racing Flight Simulator Pro) right from the start you notice just how heavy duty and well-constructed each component was in the TR160S. No component feels flimsy or not up to the task. As with my previous flight simulator cockpit motion will come to this setup so the importance of structural rigidity and quality is paramount.

Prior to starting, I closely inspected each part noticing only a few blemishes on the extrusion, nothing a wet rag wouldn’t remove, and I only found one corner bracket that had some minor surface imperfections but given where it would be located was no cause for alarm.

Tools provided:

- 1 x Size 5mm hex key

- 1 x Size 6mm hex key

- 1 x 14/17mm spanner

The included tools were quickly retired for the trusty Ryobi power drill, longer set of Allen keys and a small shifter. Bolts for the main cockpit were all presented on cardboard backing covered in transparent plastic with markings denoting the difference types allowing you to easily identify the correct size and head to use for a specific section of the build.

Manuals are all easily accessible under the track racer support section of the website which opens a PDF to guide you through the build process. The manual look well-presented and professional, I did however get tripped up on a few steps which I will discuss further into this review.

The Cockpit frame build:

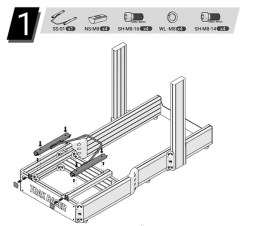

Under the strict supervision of my safety team (pictured below), I began the build which has you starting on what would become the rear of the cockpit where the seat would mount. As this was my first build using any kind of extrusion, I was curious as to how it would all come together and how difficult it would be to work with.

NOTE: As I will be adding a motion system that attaches to the outside of each corner and must be in perfectly square, so I inverted the extrusion on the left and right sides of the rear to allow for easier mounting of the motion system. This step is unnecessary if you will be using this cockpit without motion or a motion platform that does not have similar requirements about placement and alignment.

Given the cockpit would temporarily live on the RGB floor mat, I also elected to not install the rubber feet that are also included.

The rear of the cockpit is where you begin your journey and in just over an hour with the help of a well laid out manual, you’re easily through steps 1 to 7.

Steps 8 to 11 take you through the construction of the front of the cockpit. It was here I slightly deviated from the steps and elected to not install the upright extrusion (for the yoke/wheel mounts) of Step 10 until later in the build as I thought it would be easier to not have to work around any upright vertical extrusion before I was ready to mount something on it.

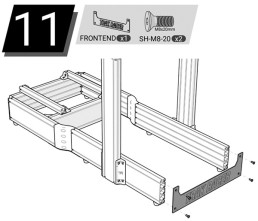

Reaching Step 11 I also found the first typo in the manual which calls for 2 x M8-20 bolts when I’m pretty sure 4 are required?

Going rogue from the manual and splashing out on 2 extra bolts finished off the last of step 11. It was however at this point that I ran into my first “oh crap” moment with bolting on the front-end plate. To this point I had built the cockpit on carpet in my living room and given it was not a hard surface allowed for some movement and misalignment as things were getting tightened down. It was at this point that I remembered a great video by Will (HERE) on steps to take when building these types of cockpits and I recommend this to anyone looking to build a similar cockpit.

Drawing on the infinite wisdom of Will, I loosened off several bolts within the metal chicane connector that then allowed enough movement to align the frontend plate and bolt into position squaring everything up nicely. From this point forward I took the approach of not overly tightening anything down allowing for some flex in the build.

Seat Assembly:

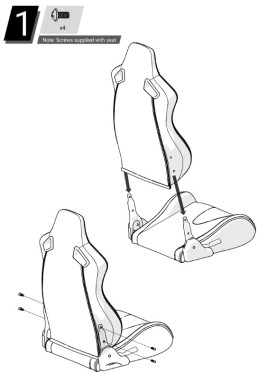

Several seat options are available for selection when purchasing your cockpit. Given that this would mainly be for flight simulation, I elected to go for a reclining seat option. I want to be in comfort fast asleep during those Trans-Tasman trips across to Wellington or passed out circling over some SA-8 just waiting to turn my virtual FA-18 into scrap metal. These seats come in two options, all black and black with red highlights. Given Red would be shown in other areas of the cockpit, I elected to go the black with red highlights for my seat selection. A small caveat does exist for recliner seats, they often are not as sturdy as the solid 1-piece seats, this flex in the back rest (while very small) can annoy some. I recorded this demonstrating it below.

Like Step 11, Step 1 of the seat assembly confronted me with yet another confusing manual anomaly surrounding bolts for the seat rails.

The manual asks for 2 different lengths to be used but doesn’t specific which length goes where? And my seat rail already had the bolts installed into them (where the seat would be secured), so which size should I use to secure the rails to the extrusion?

Taking yet another leap of faith I elected to use the longer bolts and continued on…

Resolute in my bolt choice, it was time to move onto the assemble of the seat itself. The manual has sections for each of the Trak Racer seat types and on Page 22 I found mine. In the past I’ve always struggled with getting seat backs attached to the recliner metal arms of these types of chairs. It was reassuring that yet again I faced a similar situation with this build. By this stage of my life, it’s clearly not the creators of these, it simply must be me!

Similar to the seat rails, my bolts were preinstalled into the base of the seat ready for me to remove and mate the two halves together. Upon unscrewing the bolt by the reclining mechanism, I noticed it to be twice as long as the other bolts. I imagine this is due to the stress on that corner however while it came out easily, I had a lot of trouble trying to screw it back in. It was so tight that I thought I’d either strip the bolt head or break it. Luckily neither happened and after my usual 10 minutes of practising my robust language skills got it all aligned and together.

Once joined together, there are some simple plastic covers that go over the top to hide the mechanism magic beneath, these really do add to the looks of the chair and make it feel more upmarket and premium. Closing out the install was the mounting of the seat to the frame which was without issue or swearing.

Pedal Mount:

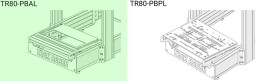

Similarly to the seats, several options are available for the pedal choices. The TR180S comes with the TR80-PBAL streamlined rudder pedal plate which is fairly limited when you compare it to the TR80-PBPL model. Given my rudder pedals have 4 large holes, mounting them should be relatively easy using the extrusion.

Installation was straight forward despite encountering a similar issue I’d faced with extrusion not aligning. Simply letting off more bolts and some light jiggling had everything slot into place. The rudder plate had a well manufactured heel plate which allows you to comfortably place your heels on the plate with your foot resting on the rudder pedals.

Yoke/Wheel Mount/ Vertical uprights:

Lastly, we arrive at the vertical uprights to mount the yoke and throttles. The TR160S does come with 2 x 160mm uprights however does not come with the linking extrusion for where a joystick or throttle may go. For this reason, I ordered the TR80-2SMEX-FS-AU which consists of 2 x Side supports and joystick/throttle mounts.

Mounting the 2 large vertical uprights was easy enough but the horizontal yoke plate proved difficult to install by myself. Given the plate needs to be aligned with 4 x T-nuts has a solid heavy construction, an additional member of the safety team was needed to assist. They simply held it in place while I bolted it in underneath.

Similarly to other parts, the fit didn’t quite come together first go and some slackening of the vertical mounts and twisting of the horizontal frame allowed for everything to line up.

Closing out the build with the remaining vertical and horizontal extrusion for the side-stick and throttles was straight forward. As I plan on having my throttles mounted on the right side, I have the throttle plate mounted to the vertical extrusion and high allowing for more flexibility later in the build as hardware on the sim grows.

Size Matters

Fully built the cockpit measures in at 660mm (26”) wide and 1445mm (56.9”) in length, a small amount of additional room should be left behind the cockpit as if you’re like me and quite tall, you may have the seat move back over the edge of the cockit to allow yourself to more gratiously dismount it.

Accessories

Transducer Mount

Continuing the haptic feedback I’ve had on previous builds, I was keen to install the Buttkicker Gamer Pro and was glad an option was available to mount this in multiple locations. Given the flexibility in this cockpit you have several options from side seat mounting to mounting front or rearward of the seat.

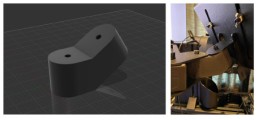

Tablet Holder

Additional displays while flying is helpful and whilst flying I’m never very far away from my iPad. While version 3 of the TR Tablet and Button Box holder Upgrade Kit works well, it’s not without what I would call a fairly large flaw. By design, the tablet will sit completely upright leading to a risk of the device falling forward and facing a similar fate as most of my landings. Hard and in a million pieces. As a mad 3d printer enthusiast, I took up the challenge of designing a small part to create an angle so I would be able to have the tablet fall back onto the mount and reduce the risk of falling forward. It also had the added benefit of being the exact angle pointed towards me whilst flying.

With the addition of the tilt bracket I was able to tilt my iPad back on a 30 degree angle allowing for the perfect position without risk of it falling forward.

Trak Mat

While definitely not required for either dodging missiles or shaving milliseconds off your lap times, the Trak Mat once powered on does bring about adding another level of refinement to the overall aesthetic. Made of neoprene it does a great job of absorbing vibrations from haptic feedback systems and can even be lit in red, and red cars go faster right?

Life beyond the assembly

At the time of producing this article, the TR160S is capable of holding my:

- Honeycomb Alpha Yoke

- Honeycomb Brave Throttles

- Winwing Orion Rudder Pedals with Dampening kit

- WINWING Orion 2 Throttle Base

- WINWING Orion 2 F16 Joystick

- VKB-Sim Gunfighter Mk IV Space Combat Stick (Left handed)

- StreamDeck +

The rigidity observed throughout the build is evident once you put the cockpit to use. Once flight controls are on and you’re really throwing it around I observed very little movement throughout the cockpit. However, the real test for me would be the addition of a motion system such as the Sigma Integrale’s fantastic DK2+ system. I will cover the specifics of this motion system in a separate review however given the power this has, I was very interested to see how the TR160S held up under some extreme conditions such as every one of my landings.

Thanks to some decisions made earlier in the build, mounting each of the DK2+ 4 actuators was done with ease and within just a few minutes I was ready for a shakin’ good time.

A few sessions of DCS (Digital Combat Simulator) in both helicopters and the F18 Hornet resulting in many moments of extreme violence and shocks being sent through the TR160S. After many weeks of bumps, bounces, shocks, explosions and a few hard landings I’m happy to say that the cockpit has shown no signs of coming loose or failure. Comparatively to other simulator cockpits I’ve owned, this is a very sturdy well-designed cockpit.

Is it comfy?

Well I’m 6ft, 85kg (80 if anyone asks) size 32 waist (heading to 34 if I have that chocolate in the fridge) and I sit comfortable in the chair and have good overall support and the movement of the seat along the rails is solid and feels well-constructed. I do find however that the seat could benefit from a few additions.

I’d like to see a cushion offered standard like others in this market, to help push the bottom of your back out as I did find over time I would get a stiff lower back (My landings might of played a role in this however). Additionally, given the nature of use for this cockpit being primarily flight orientated, I’d like to see the exact same seat with a cutout between your legs to better aid in mounting centre sticks. None in the range have this and you must mount your stick high enough to clear the seat when you pull it forward. For sticks with relatively tall bases this can lead to have the stick higher than what you would otherwise have it that could impact comfortability.

Conclusion

Overall, the TR160S from Trak Racer is a robust and well-constructed cockpit option for anyone looking for a home flight cockpit. It’s versatile, made of high-quality components and is easy to build.

Despite a few minor marks on the extrusion and the odd inconsistences in the manual, if its your first time building these cockpits or you’re a seasoned professional, you’ll have an easy time following the instructions and getting this built over a day or two.

While the seat is comfortable most of the time, some additional padding of cushioning and some design considerations for flight simulator users would be appreciated. The TR160S is a premium product that delivered on the promise of strength and quality making it an excellent contender for anyone considering one of these home cockpits. I have little doubt that it’s not up to the task of either being used trackside or airside as you take the battle to the virtual track or skies.

Pros

- Strength, 160 x 40mm profile in the main body shows no signs of weakness or areas that could fail over time.

- Flexibility, the additional Flight Sim Control Mounts offer flexibility to whatever you’re flying or driving

- The red just looks great, mated with a Trak Mat in red makes this thing really pop!

Cons

- Manual, overall, its well-presented and looks professional, there is the odd area here and there that could be either expanded on or clarified.

- The Seat, while comfortable, over time it becomes less so and without a cutout for a centre stick, I feel there was a real opportunity missed to bring about a overall fantastic cockpit

Check out more Reviews by Boosted Media

November 1, 2024

Sim Racing Black Friday Deals

March 18, 2024

WINWING Orion Metal Flight Rudder Pedals – REVIEW

February 17, 2024